The old saying, ‘more haste, less speed’, is often true when you’re working quickly. The more you hurry, the more chance there is to make a mistake that slows you down! Often it’s something harmless, like sending an email without an attachment – but in the laboratory or production plant, a mistake could mean expensive waste or downtime.

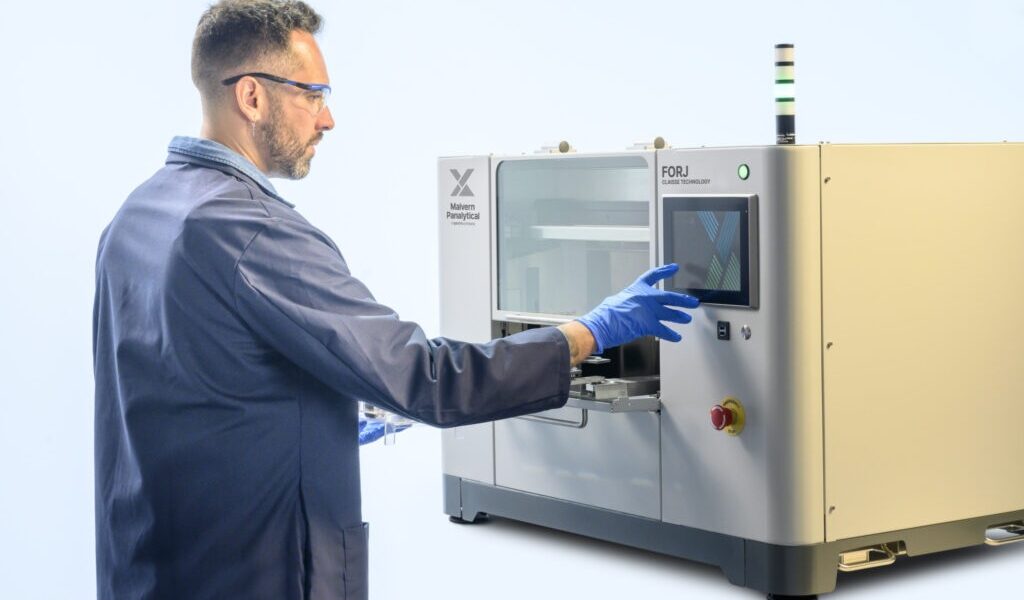

Many industries demand high throughput in their laboratories (after all, time is money!). Mining and cement labs, for example, can require up to 300 samples processed per day, working around the clock. But working this quickly can strain your analytical processes, and sample preparation is often a bottleneck. Or at least, it was before FORJ™ Claisse Technology.

Why use fusion?

Several very common analytical methods call for fusion sample preparation – including X-ray fluorescence (XRF), inductively coupled plasma mass spectrometry (ICP), and atomic absorption spectrometry (AA). Fusion produces higher-quality samples and more accurate results than other methods, such as pressed pellets. But the high heat required for fusion can slow down the overall process as you wait for samples to heat up and cool down.

But the new FORJ fusion instrument has changed this for good! It ensures shorter fusion times and higher success rates – delivering increased productivity overall. Here’s how:

Ramp up the heat

With better defined heat ramps and set temperatures reached more quickly, FORJ speeds up the heating process to reach the fusion stage as soon as possible. With less material inside the furnace, the instrument heats more efficiently – and a convenient handling mechanism eliminates the need to open the furnace, avoiding temperature drops.

Swirled, not stirred (or rocked)

Most electrical fusion instruments use a rocking motion to agitate the molten mixture inside the crucibles. But FORJ crucibles swirl instead, making sample dissolution faster and increasing the homogeneity of the mixture. This simple difference can save up to 20-25% of time spent depending on the application!

Drop it like it’s hot

Fusion is a complex process, but it can feel frustratingly simple to be waiting around for your sample to just cool down! The FORJ furnace cools much more quickly than others, and is able to drop temperatures by 550 °C in 10 minutes – quite an achievement compared with the 90 minutes that many other instruments take for the same reduction.

This is achieved by opening the furnace chamber at the end of the fusion cycle while the safety doors remain closed, with the extra-efficient FORJ fans running at full power.

Efficiency – a win-win solution

Many industries today are trying to find good ways to maximize productivity and efficiency – not only for profit, but also for the planet. Cutting waste and streamlining processes are powerful levers that companies can use to achieve sustainability goals in a way that’s also sustainable for their business, saving them money and boosting profitability.

But now, all the time wasted on slow sample fusion can be checked off that list. There’s no reason to wait around – rely on FORJ!

Discover the full FORJ specifications and download a brochure here.

This blog is part of a series highlighting the value added by FORJ technology – read our earlier FORJ introduction here, and learn about its robustness here!

We’ll be back soon with a new blog article on FORJ – stay tuned.